| T-300K Pixel LED Controller Tutorial |

I have talked about offline pixel led controllers in our previous articles but today I'm going to talk about a different type of pixel led controller T-300K addressable pixel led controller .This controller is special due to the fact that this controller can work as both offline and online pixel led controller. Prize wise this is a every expensive controller (around $ 130). But it has some features that makes it worth every penny you spent on this controller . Since this controller can be used as a online controller this controller can be used with live events such as musical concerts and other live events where you can control the display real-time. I'm going to brake this lesson it to two articles .This one will be about offline control .The second one is about Online control [Click Here].

T-300K Pixel LED Controller Specifications

Supply Voltage (AC) : 110-240V

Working voltage (DC): DC5V

Working temperature : -30°C ~ +85°C

Weight: 1.35KG

Working power : 8W

Product Size : L270mm×W180mm×H55mm

Max. LEDs : 8192

Controller Type: Online/Offline

Working temperature : -30°C ~ +85°C

Weight: 1.35KG

Working power : 8W

Product Size : L270mm×W180mm×H55mm

Max. LEDs : 8192

Controller Type: Online/Offline

Memory card type : SD card

Memory card Capacity : 128MB-2GB

Memory card Format : FAT

Memory card Capacity : 128MB-2GB

Memory card Format : FAT

Features

T-300K Pixel LED Drivers can drive up to 8192 LEDs .You can connect maximum of 1024 LEDs per port .There are 8 ports .The offline features are very identical to the T-8000 controller .It has controller networking capability (cascading) as in the T-8000 Pixel LED controller .Supports both 3 wire Pixel LED strings or Strips ( Vcc,Data,Gnd ) and 4 wire LED strings or Strips ( Vcc,Data,Clock,Gnd ). Also supports RS485 based Pixel LED strips or strings.Most impotently it supports both offline an online operation.

Frame Rate

Frame rate is a impotent thing when it comes to Pixel LED Programming ,Greater the frame rate ,Smoother the frame transition , Low frame rate means rough transition , you will start to see the frame by frame transition.

If you are using less than 512 LEDs or Pixels per port you can use the 30fps (Frames per seconds) as the frame rate of the animation or the video .If you are using greater than 512 LEDs or Pixels per port the frame rate will be automatically reduces .

Offline Operation

Without the controller connected to a PC via Network cable the controller is pretty much a T-8000 controller .You can upload the LED pattern file in to your SD-card and insert that SD card in to the controller ( Turn off the controller before plug-in the SD card ) and the controller will start playing the patterns in the SD card .In this article I will explain the offline mode of T-300K pixel led controller .

Software

The software plays the most important part when it comes to Pixel LED programming .LEDEdit is the most advanced and most developed Pixel LED programming softwar available today. In order to program T-300K controller you need LEDEdit 2013 or later software versions .Please download and install the latest LEDEdit software version from below link before continuing .

When you are selecting the controller from the list please follow this method .

Controller Name in the list = Controller Name + Drive chip Name

Eg- If your controller name is T-300K and Drive chip name is WS2811, You should select T-300K-WS2811 from the list .

If you like to know more on how to use LEDEdit software please visit [THIS Article] .

Supported Pixel LED Drive chips :

TM1803,TM1804,TM1809,TM1812,TM1829,TM1913,TM1914,UCS1903,UCS1903B,

UCS1909B,UCS1912,UCS2903,UCS2909,UCS2912,UCS3903,UCS6909,UCS6912,UCS7009,

UCS5903,UCS8903,UCS512,US2811,WS2821,P9813,P9823,LPD1886,GW6202,GW6201,

GW6202B,GW6204,GW6203,GW623X,TA9909,MBI6021,INK1003,LX10003,LX2003,

LX2006,TLS3100,DMX,SM16711,SM16726,SM16716,LPD6803,LPD8806,LPD1882,LPD6812,

TM1903,TM1904,TM1909,TM1912,DMX,Monochrome,WS2801,WS2803,D7710,QC1109,

TLS3001,TLS3008,APA102,MY9221,BS0815,BS0825,BS0901,HL32,HL1809,HL2803,

RGB,Monochrome,XB001,XB002.

Note : Not every T-300K controller supports the above listed driver chips .Please consider asking from your seller about supported LED drive chip names .

Note : Not every T-300K controller supports the above listed driver chips .Please consider asking from your seller about supported LED drive chip names .

Pin-Out T-300K Controller

|

| Pin-Out T-300K Controller |

Please refer to the above picture for pin output definitions .

AC IN : Power in 110 - 240Vac

Port Pins ( Communication )

CLK : Clock Out ( For 4 wire Strings )

DAT : Data Out ( For 3 wire and 4 Wire Strings )

GND : Data Ground ( Common )

Network Mode (Synchronized)

NET 1 : Output line to next controller /Computer .

NET 2 : Same Function as NET 1 / Not connected .

NET 3 : Same Function as NET 4 / Not connected .

NET 4 : Input line from Previous controller / Computer .

AC IN : Power in 110 - 240Vac

Port Pins ( Communication )

CLK : Clock Out ( For 4 wire Strings )

DAT : Data Out ( For 3 wire and 4 Wire Strings )

GND : Data Ground ( Common )

Network Mode (Synchronized)

NET 1 : Output line to next controller /Computer .

NET 2 : Same Function as NET 1 / Not connected .

NET 3 : Same Function as NET 4 / Not connected .

NET 4 : Input line from Previous controller / Computer .

Networking Controllers ( Cascading )

Imagine a situation that you had to control more than 8192 LEDs / Pixels ,Then you have to use more than one controller . Now you have to face another problem , How to synchronize these two or more controllers ,That's where Networking / Cascading feature becomes very handy . You can network all the controllers together so that all the controllers can synchronize their patterns besides that you only have to use one SD card which contains led pattern file for every controller in the network. That SD card have inserted to the first controller of the network . By using this method you can network up to 37 controllers which means up to 300,000 Pixels or LEDs can be controlled but make sure to use quality high speed RJ45 cables (CAT5e ,CAT6) and use short cable length as possible.

[Click Here for more information on Networking Controllers]

[Click Here for more information on Networking Controllers]

Wiring Methods

There are basically four wiring methods for offline mode of this controller .It's almost identical to T-8000 controller wiring methods .

Wiring Method 1 - ( Single controller with 3 wire LED Strings )

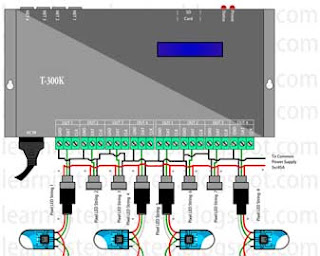

|

| Wiring Method 1 T-300K LED Controller |

In this method 3 wire (VCC,DATA,GND) pixel LED strips /strings are connected to each controller port. All the GND wires of the pixel LED strips /strings , data GNDs of the controller and ground of the common power supply is connected together . Since the LED strips /strings are powered by a single common power supply VCC (5V) of the power supply is connected to the VCC of each LED strips /string . You can use more than one power supply .Make sure all the ground's are connected together (Common Ground) . Please consider reading my [THIS Article] about selecting a power supply for your Pixel LED Project .Below is the connection table .

|

| T-300K LED Controller Connection table 1 |

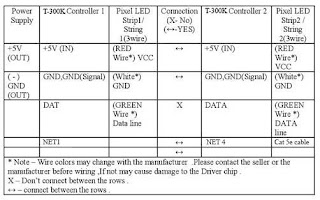

Wiring Diagram 2 ( Multiple controller with 3 wire LED Strings )

|

| T-300K Wiring Diagram 2 |

In this method 3 wire (VCC,DATA,GND) pixel LED strips /strings are connected to each controller's ports .The two or more controllers are connected together VIA RJ45 port using a network cables ( cat5e ,cat6 ) .Previous controller's NET 1 port is connected with the next controller's NET4 .You can network up to 37 controllers this way .Make sure that you use hi-speed network cables that short as possible . Two power supplies are supplying the power required .Here is the connection table .

|

| T-300K Connection Table 2 |

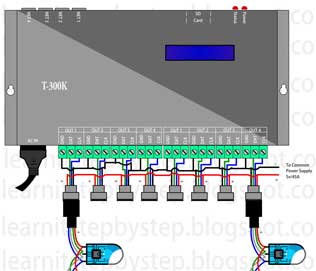

|

| Wiring Method 3 T-300K LED Controller |

In this method 4 wire (VCC,DATA,CLOCK,GND) pixel LED strips /strings are connected to each controller port. All the GND wires of the pixel LED strips /strings , data GNDs of the controller and ground of the common power supply is connected together .The LED strips /strings are powered by a single common power supply .Here is the connection table .

|

| T-300K LED Controller Connection table 3 |

Wiring Diagram 4 ( Multiple Controllers with 4 wire LED Strings )

In this method 4 wire (VCC,DATA,CLK,GND) pixel LED strips /strings are

connected to each controller's ports .The two or more controllers are

connected together VIA RJ45 port using a network cables ( cat5e ,cat6 )

.Previous controller's NET 1 port is connected with the next

controller's NET4 .You can network up to 37 controllers this way .Make

sure that you use hi-speed network cables that short as possible . Two

power supplies are supplying the power required .Here is the connection

table.

Limitations

- When it comes to these controllers there are some limitations when it comes to controlling large amount of pixel LEDs .Here are the limitations .

- Maximum number of LEDs per port is 1024.

- Maximum Controllers on a network is 37 .

- 256 Gray level support is only when you have less than 512 pixel LEDs per port .If you are using more than 512 pixel LEDs per port you have to use 32 Gray levels .

- 30Frames per second is only supported when you have less than 512 pixel LEDs per port .If you are using more than that you have to use a less frame rate like 20 Fps .

Program File placement

The program file placement inside the SD card depends on the controller usage.

Single Controller

| Single T-300K controller file placement |

If you are using a single controller or multi controllers without

networking them(In this case every controller have a individual SD card

), The file placement for each controller SD card would be like this -

first two digits stands for program number (00 to 16) ,Since we use

single SD card for each controller The last digit is always "1" .

Multiple Controllers Networked

| T-300K Multiple Controllers file placement |

If you are using a multiple controllers networked together ,You only needs a single SD cad inserted in to the first controller in the network .You can place the each controllers programs inside that SD card. above picture shows how to place those program files.first two digits stands for program number (00 to 16) ,The digits after the "_" character is the controller number starting from "1" .

Eg -

Controller 1 program files - 00_1.led ,01_1.led,02_1.led,03_1.led,04_1.led

Controller 2 program files - 00_2.led ,01_2.led,02_2.led,03_2.led,04_2.led

Controller 3 program files - 00_3.led ,01_3.led,02_3.led,03_3.led,04_3.led

Controller 4 program files - 00_4.led ,01_4.led,02_4.led,03_4.led,04_4.led

Eg -

Controller 1 program files - 00_1.led ,01_1.led,02_1.led,03_1.led,04_1.led

Controller 2 program files - 00_2.led ,01_2.led,02_2.led,03_2.led,04_2.led

Controller 3 program files - 00_3.led ,01_3.led,02_3.led,03_3.led,04_3.led

Controller 4 program files - 00_4.led ,01_4.led,02_4.led,03_4.led,04_4.led

Troubleshooting T-8000 Controller

Problem - Error LED flashing , No display

This is may due to few reasons -

*. Controller cant detect the SD card - Damaged SD card,Unsupported SD card ,Unsupported file format.

fix - Check whether the SD cad is supported type (128,256,512,1GB,2GB SD card) ,Insert it to the card reader and format it using the windows format tool as I mentioned previously in this tutorial .replace the files again and try again .

*. Oxidized card pins or controller pins - remove the card and check the gold plating of the pins if they where damaged and gold plate was gone replace the card .If the controller port is damaged and the plated gold was gone ,You have to replace the port .

*. Unknown file type or no file - The file type should be ".led" other file types may cause error light to flash. please recheck the files using a PC .

*. Different controller Type - If you have selected T-1000-XXXX instead of T-300K-XXXX it will cause an error .

No error light flashing but no LED effect either

This is due to physical error - Damage wires in the LED String or Damaged or oxidized port or connectors or due to selecting wrong drive chip type in the new project window check the "Selecting the Controller in the Software " section at the top of this article. If the ports are damaged ,you have to re-solder them .If connectors are oxidized you have to use NC-Tinner to clean them ,You can use a used tooth brush and dip it in NC Tinner and brush the oxidized parts of the controller and the LED String or use contact cleaner spray.

Warnings

Hot Swapping - Never ever Pullout / Remove the SD card from the controller while the power is on (This will damage your SD card permanently or if you are lucky you can getaway with only file lost /Damage) . Always power off the controller wait for a few seconds and remove the card .

Never ever reverse the polarity .Reverse polarity protection may or may not in your controller or LED String .If there is no protection it will damage the controller and Pixel LED Driver I.C .Use a multi-meter to check the polarity of the power supply output before wiring .

Since there are thousands of different manufacturers , Wire colors may change with the manufacturer .Please contact the seller or the manufacturer before wiring ,If not may cause damage to the Driver chip .

Check the Feedback of the sellers before buying online .There are many fake or damaged controllers , Pixel LED strings are available on the internet .(Be aware of scammers )

Limit the amount of time you insert and remove the SD card to the controller , Because every time you doing this will cause the gold plated pins to scratch which will lead to oxidizing of the pins .

Environmental conditions may cause damage to your led string and the LED controller ,The controllers are not designed for out-door use, It's for indoor use only .If you are putting the LED string out-door please make sure to use the water sealed LED strings. But even the water sealed led strings may damage due to hash environmental conditions .

Never ever reverse the polarity .Reverse polarity protection may or may not in your controller or LED String .If there is no protection it will damage the controller and Pixel LED Driver I.C .Use a multi-meter to check the polarity of the power supply output before wiring .

Since there are thousands of different manufacturers , Wire colors may change with the manufacturer .Please contact the seller or the manufacturer before wiring ,If not may cause damage to the Driver chip .

Check the Feedback of the sellers before buying online .There are many fake or damaged controllers , Pixel LED strings are available on the internet .(Be aware of scammers )

Limit the amount of time you insert and remove the SD card to the controller , Because every time you doing this will cause the gold plated pins to scratch which will lead to oxidizing of the pins .

Environmental conditions may cause damage to your led string and the LED controller ,The controllers are not designed for out-door use, It's for indoor use only .If you are putting the LED string out-door please make sure to use the water sealed LED strings. But even the water sealed led strings may damage due to hash environmental conditions .

2 comments:

You write that you only need one SD card in the first controller. Unfortunately it doesn't work. I have done many attempts and I cannot start the network with one sd card on T300K. I will be grateful for your help. Thomas

Sorry , I was wrong .. Each controller requires SD card .. Networking will only synchronize the playback !

Post a Comment